We detected, that your browser supports another language than the called one. This page is also available in your language! Would you switch to this page in your language?

Original SCHNORR®

Bearing preload springs type “K“

Preloaded bearing springs have a smaller flank (ratio OD / ID) than standard disc springs due to the small installation space available.

Some ball bearing applications require a "softer deflection behaviour" at the beginning of deflection. This means a lot of deflection must generated with as little increase in spring force as possible. For this special case SCHNORR® has developed the slotted bearing springs. Due to the slotted geometry these springs can precisely meet the requirement.

As a result of the very different dimensions of these springs compared with "normal" disc springs as defined in DIN EN 16983, the load and dimensional tolerances of disc springs designed for ball bearings do not coincide with the tolerance values in DIN EN 16983.

The optimal supplement for ball bearings

Two problems continually occupy design engineers using bearings, the reduction in noise and the elimination of play in ball bearings. A solution of both these problems has been achieved by Schnorr working in close cooperation with well-known ball bearings manufacturers. The fitting of a special version of our disc springs effectively reduces both problems and frequently results in simpler designs.

Fitting of bearing preload springs

The drawing illustrates how the outer ring of the ball bearing usually is correctly preloaded using a disc spring “K“ series. Depending on the requirements of the design, one or more disc springs can be used. In some cases it is preferable to preload the inner ring of the bearing. That is why the bore holes of disc springs for ball bearings were chosen in such a way that they match the internal diameter of an other ball bearing size. That way, a disc spring suitable for pushing the external ring of the ball bearing 6302, for example, can also be used to pretension the inner rings of the ball bearings 6205 and 6305.

Key advantages speak for bearing preload springs

An important advantage of “K“ disc springs is being round.

That ensures an equal bearing surface when multiple discs are installed. As with standard disc springs, here it also applies that in alternating arrangement with the constant force the spring deflections add up, while in case of parallel layering (same laying in) with constant spring deflection the loads add up. As all springs have a strongly digressive spring characteristic (great ho/t), the spring force continues to be almost constant over a large deflection range.

Apart from the compensation for play, this brings the following advantages:

- The tolerance built up in the assembly can be accomodated without significant change in preload.

- Length variations due to heat impact are absorbed.

- Any subsequent axial movement of the assembly does not alter the preload significantly.

Within the following product finder you will find disc springs manufactured of the following materials:

- Standard materials acc. to DIN EN 10132-4

Further versions:

Furthermore, we also manufacture from special materials.

For this, please see our material grade overview table and contact our sales department.

Productfinder

Disc Springs

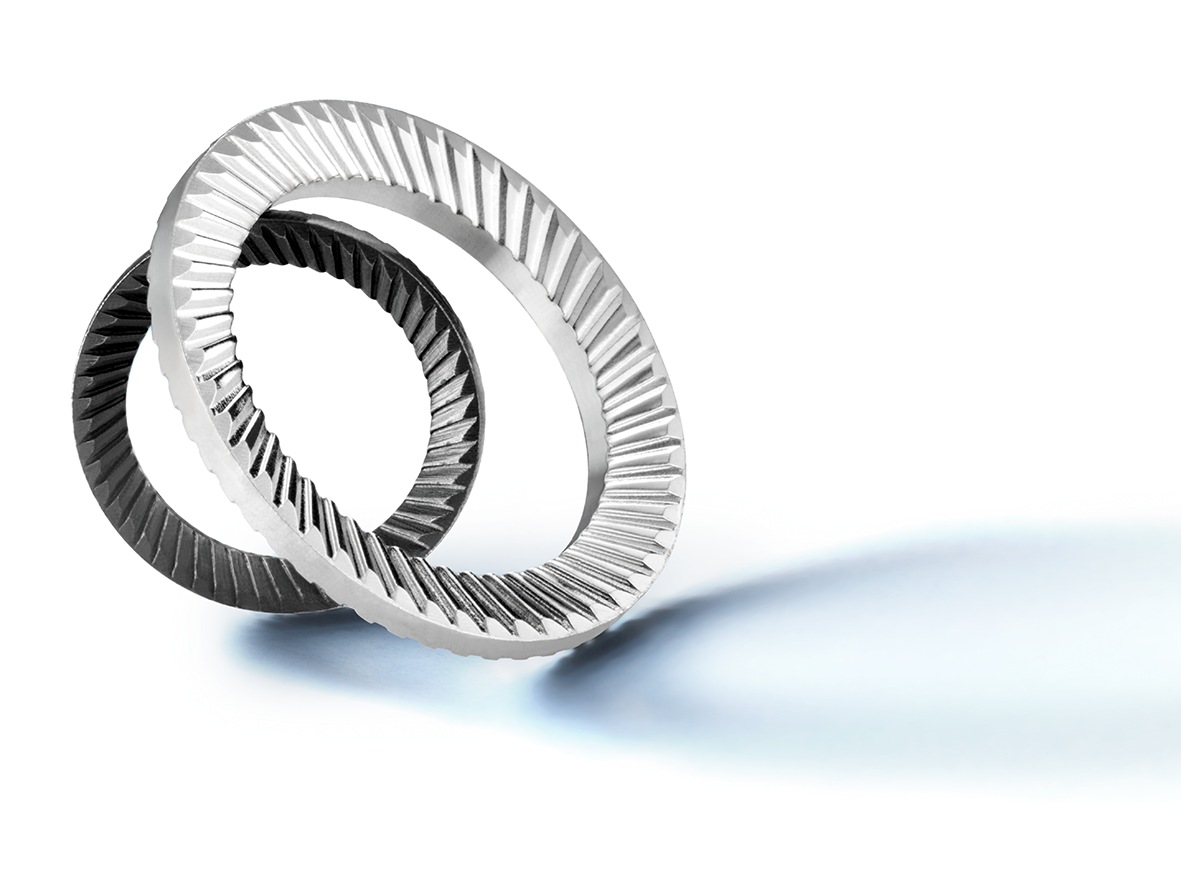

Screw & Bolt Locking Systems

| Ordering Dimensions | Deflection s/Force F | Weight | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Article Number | De [mm] | Di [mm] | t [mm] | t' [mm] | l0 [mm] | h0 [mm] | s [mm] | F [N] | Weight per 1000 pieces [kg] | |

| 246 700 | 189 | 121 | 2 | 0 | 4.3 | 2.3 | 1.73 | 759 | 258.3 | |

| 246 600 | 179 | 126 | 2 | 0 | 4.2 | 2.2 | 1.65 | 928 | 197.8 | |

| 246 500 | 179 | 121 | 2 | 0 | 4.2 | 2.2 | 1.65 | 864 | 213.1 | |

| 246 400 | 169 | 121 | 1.5 | 0 | 3.8 | 2.3 | 1.73 | 546 | 127.7 | |

| 246 300 | 169 | 111 | 1.5 | 0 | 3.8 | 2.3 | 1.73 | 470 | 149.2 | |

| 246 200 | 159 | 111 | 1.5 | 0 | 3.5 | 2 | 1.5 | 477 | 118.9 | |

| 246 100 | 159 | 101 | 1.5 | 0 | 3.5 | 2 | 1.5 | 412 | 138.5 | |

| 246 000 | 149 | 106 | 1.5 | 0 | 3.2 | 1.7 | 1.28 | 450 | 100.5 | |

| 245 900 | 149 | 95.5 | 1.5 | 0 | 3.2 | 1.7 | 1.28 | 379 | 120.1 | |

| 245 800 | 139 | 101 | 1.25 | 0 | 3.25 | 2 | 1.5 | 429 | 69.58 | |

| 245 700 | 139 | 90.5 | 1.25 | 0 | 3.25 | 2 | 1.5 | 354 | 85.11 | |

| 245 600 | 129 | 95.5 | 1.25 | 0 | 3.2 | 1.95 | 1.46 | 500 | 57.31 | |

| 245 500 | 129 | 85.5 | 1.25 | 0 | 3.2 | 1.95 | 1.46 | 405 | 71.28 | |

| 245 400 | 124 | 90.5 | 1.25 | 0 | 3 | 1.75 | 1.31 | 445 | 54.75 | |

| 245 300 | 119 | 85.5 | 1.25 | 0 | 2.8 | 1.55 | 1.16 | 393 | 52.28 | |

| 245 200 | 119 | 75.5 | 1.25 | 0 | 2.8 | 1.55 | 1.16 | 320 | 64.71 | |

| 245 100 | 114 | 90.5 | 1.25 | 0 | 2.45 | 1.2 | 0.9 | 398 | 36.49 | |

| 245 000 | 109 | 75.5 | 1.25 | 0 | 2.7 | 1.45 | 1.09 | 398 | 47.17 | |

| 244 900 | 109 | 70.5 | 1.25 | 0 | 2.7 | 1.45 | 1.09 | 357 | 52.8 | |

| 244 800 | 99 | 70.5 | 1 | 0 | 2.6 | 1.6 | 1.2 | 332 | 29.44 | |

Screw & Bolt Locking Systems

| Size | Ordering dimensions | Weight/Quantity | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Article Number | Surface | Nominal size [mm] | D2 [mm] | D1 [mm] | s [mm] | hmin [mm] | hmax [mm] | Weight per 1000 pieces [kg] | |

| 420 400 | blackened | 8 | 13 | 8.4 | 0.9 | 1.4 | 0.37 | CAD Download | |

| 451 000 | Zn8M + Passivation | 8 | 13 | 8.4 | 0.9 | 1.4 | 0.37 | CAD Download | |

| 423 000 | blackened | 10 | 16 | 10.5 | 1.1 | 1.6 | 0.68 | CAD Download | |

| 451 100 | Zn8M + Passivation | 10 | 16 | 10.5 | 1.1 | 1.6 | 0.68 | CAD Download | |

| 425 100 | blackened | 11.1 | 15.9 | 11.6 | 1.05 | 1.6 | 0.56 | CAD Download | |

| 451 200 | Zn8M + Passivation | 11.1 | 15.9 | 11.6 | 1.05 | 1.6 | 0.56 | CAD Download | |

| 426 200 | blackened | 12 | 18 | 13 | 1.15 | 1.7 | 0.79 | CAD Download | |

| 451 300 | Zn8M + Passivation | 12 | 18 | 13 | 1.15 | 1.7 | 0.79 | CAD Download | |

| 427 900 | blackened | 12.7 | 19 | 13.7 | 1.25 | 1.8 | 0.89 | CAD Download | |

| 451 400 | Zn8M + Passivation | 12.7 | 19 | 13.7 | 1.25 | 1.8 | 0.89 | CAD Download | |

| 429 100 | blackened | 14 | 22 | 15 | 1.35 | 2 | 1.5 | CAD Download | |

| 451 500 | Zn8M + Passivation | 14 | 22 | 15 | 1.35 | 2 | 1.5 | CAD Download | |

| 430 700 | blackened | 16 | 24 | 17 | 1.55 | 2.1 | 1.79 | CAD Download | |

| 451 600 | Zn8M + Passivation | 16 | 24 | 17 | 1.55 | 2.1 | 1.79 | CAD Download | |

| 432 400 | blackened | 18 | 27 | 19 | 1.75 | 2.3 | 2.72 | CAD Download | |

| 451 700 | Zn8M + Passivation | 18 | 27 | 19 | 1.75 | 2.3 | 2.72 | CAD Download | |

| 433 800 | blackened | 19 | 30 | 20 | 1.9 | 2.5 | 3.79 | CAD Download | |

| 451 800 | Zn8M + Passivation | 19 | 30 | 20 | 1.9 | 2.5 | 3.79 | CAD Download | |

| 435 100 | blackened | 20 | 30 | 21 | 1.85 | 2.5 | 3.42 | CAD Download | |

| 451 900 | Zn8M + Passivation | 20 | 30 | 21 | 1.85 | 2.5 | 3.42 | CAD Download | |